KANSAS CITY — Consumers, especially parents, are checking lists, perhaps twice, but it has nothing to do with presents under a tree. Instead, they scan ingredient lists, checking to make sure certain ingredients are not there: ingredients with names like sodium stearoyl lactylate (SSL), azodicarbonamide (ADA), calcium stearoyl lactylate (CSL) and potassium bromate.

Companies in the baked foods industry, both food manufacturers and ingredient suppliers, are working to stay in step with the no-no lists. Efforts that should help in this clean label pursuit include Kemin Industries, Des Moines, Iowa, opening a bakery innovation center this year and Lesaffre, which has a U.S. office in Milwaukee, recently completing an acquisition. Several company booths at the International Baking Industry Exposition held in September in Las Vegas exemplified how ingredient suppliers are emphasizing alternatives to replace more chemical-sounding ingredients.

“Most bakers and consumers are looking for the removal of ingredients with chemical names, like SSL, L-cysteine, ADA, calcium propionate, bromate and mono- and di- glycerides,” said Rob Nordin, Southeastern regional sales with Brolite Products, Bartlett, Ill. “They are also looking to remove artificial flavors and colors. Consumers not only want a label with less chemical names, though. They want a label with less in general: shorter ingredient lists, the better.”

Enzymes, gums, cultured ferments and starches have been shown to work as replacements, he said.

“Most of the time, the best result is a combination of ingredients,” Mr. Nordin said. “For flavors and coloring, bakers are moving toward natural ingredients.”

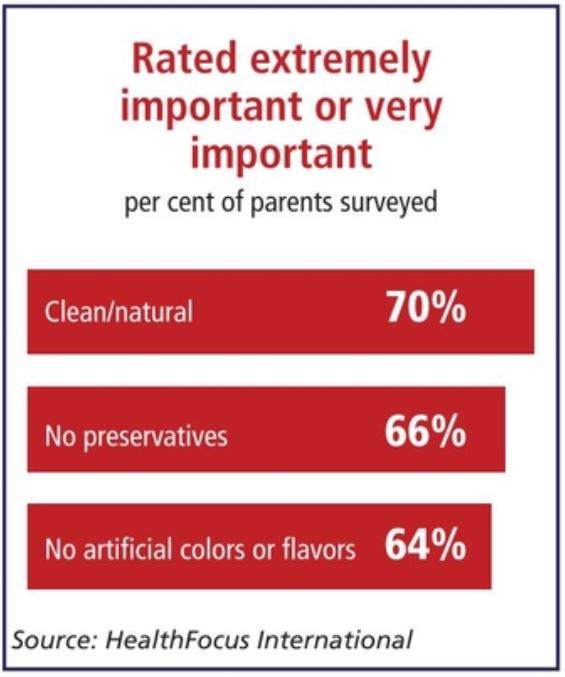

Such natural ingredients especially may appeal to younger people and those with children. A 2019 report involving 22 countries from HealthFocus International, St. Petersburg, Fla., found 63% of total shoppers said they were extremely interested or very interested in eating clean. Within that 63%, 72% said they wanted to avoid chemicals and artificial ingredients in their food.

Seventy per cent of parents said a clean/natural product was either extremely important or very important when purchasing products for their children. Sixty-six per cent of parents ranked no preservatives as extremely important or very important, and 64% ranked no artificial colors or flavors as extremely important or very important.

“While clean label is sought after across many demographics, the millennial generation tends to seek out more clean label products than older generations,” said Emily Guilfoyle, bakery R.&D. manager for Kemin Industries. “In addition, households with a higher income and those with children tend to seek out clean label alternatives due to the belief that clean label products are better for them and their families.”

Kemin Industries in October opened a new bakery innovation center at its global headquarters in Des Moines where company researchers work together with Kemin’s customers. The 2,300-square-foot facility features a lab to evaluate baked foods for texture and microbial stability, a dry blending center with the capabilities needed to develop new concentrates, premixes, batch packs and individual components, and pilot scale production capabilities.

The baking industry is seeking alternatives for emulsifiers, calcium propionate, sodium metabisulfite and potassium sorbate, Ms. Guilfoyle said.

“Processing challenges can be seen in the dough and looking at the yield of your finished products,” Ms. Guilfoyle said. “Using these replacement ingredients can cause macro and micro textural changes in the finished products. Volume, puffiness and microstructure of the finished product can get affected.

“A wise baker once told me the rule of three: Change one thing in a product process and formulation and expect a minimum of three things to change down the line. Understanding those changes is both an art and a science that needs to be monitored with ingredient substitutions. Lastly, ingredients are very application specific. Working together with a supplier partner, ingredient experts can expedite development and launch time and prevent waste of valuable resources.”

Lesaffre expanded its ability to remove no-no ingredients in July 2018 when the company acquired Delavau Food Partners, a baking ingredients company based in Piscataway, N.J. Delavau under its Encore line of baking products offers enzyme-based and other dough improvers for softness, shelf life, mold inhibition, dough relaxing and strength.

“A wise baker once told me the rule of three: Change one thing in a product process and formulation and expect a minimum of three things to change down the line." — Emily Guilfoyle, Kemin Industries

“This acquisition enabled Lesaffre and Delavau to fill in each company’s gaps,” said Arnaud Deniaud, vice-president of technical services for Lesaffre. “Delavau brought to Lesaffre its Encore portfolio of ingredients as well as technical expertise in developing custom solutions. In turn, Lesaffre opened the entire baking industry to Delavau’s expertise. Additionally, our Delavau Bakery Partners by SafPro group works in collaboration with customers in our East coast baking center to tackle challenges many C.P.G. and food service companies face, including clean label formulation.”

At IBIE, the Delavau Bakery Partners by SafPro booth showcased two Encore systems. Encore Fresh delivers mold inhibition while maintaining a desirable eating experience. Encore Soft anti-staling ingredients improve both the quality and longevity of the eating experience. Both ingredients have been shown to replace calcium propionate.

“Encore Fresh has successfully extended the shelf life of pita from 10 to 21 days, and other ideal applications include flatbreads, donuts, cakes, rolls, pizza dough, bread and more,” Mr. Deniaud said. “Encore Soft extended the freshness of a shelf-stable snack cake from 30 to 45 days and doubled the lifespan of a yeast-raised donut from 18 to 36 hours.”

Encore Plus, which combines the capabilities of Encore Fresh and Encore Soft, features anti-staling and antimicrobial systems for extended freshness and shelf life while retaining rollability in tortillas, he said. Encore Plus also has been shown to extend shelf life in applications like bread, cookies and cakes.

LeSaffre at IBIE also promoted Saf-Pro XtendLife, a natural mold inhibitor. The fermented ingredient blend inhibits mold growth to extend the shelf life of finished products without imparting an off-flavor.

LeSaffre at IBIE also promoted Saf-Pro XtendLife, a natural mold inhibitor. The fermented ingredient blend inhibits mold growth to extend the shelf life of finished products without imparting an off-flavor.

“Ideal applications for XtendLife include bread, buns, rolls, bagels and pizza crusts,” Mr. Deniaud said.

Corbion, which has a U.S. office in Lenexa, Kas., promoted its Verdad MP 100 mold inhibitors at IBIE. Verdad MP 100, a combination of vinegar and natural flavor, matches the mold-inhibiting functionality and flavor neutrality of calcium propionate, according to Corbion.

Cain Food Products, Dallas, offers AlphaFresh, a fermented wheat that replaces calcium propionate in all flour-based foods, said Matt Feder, senior vice-president of sales. The shelf life a customer is looking for determines the use level, he said.

“We typically start at a 2-to-1 replacement of calcium propionate level and reduce usage based on the shelf-life studies,” Mr. Feder said.

Cain Food Products’ customers also are looking to replace DATEM (diacetyl tartaric acid ester of mono- and di-glycerides), SSL, CSL, mono- and di-glycerides, and ADA. To replace them, Cain uses enzyme systems, either single dose, the company’s N-Hance line or a combination of products like TRU CL, Oxibake CL and CLDC, along with ascorbic acid.

“All the above product solutions have been used in plant applications for years with great results,” Mr. Feder said.